An incremental rotary encoder is a device that measures rotational movement and provides precise feedback. It plays a vital role in determining position, speed, and direction in various systems. You can find these encoders in industrial automation, where they ensure accurate control of machinery. For example, they are essential in conveyor systems, helping sort and place items efficiently. As automation grows, the demand for these encoders continues to rise, driven by their ability to enhance productivity and precision in modern technology.

Key Takeaways

- Incremental rotary encoders change spinning motion into electrical signals. They give exact details about position, speed, and direction.

- These encoders are affordable and easy to use. This makes them great for many jobs in factories and robots.

- The A and B channels in these encoders make pulse signals. These signals help find direction and improve accuracy.

- There are three main types: optical, magnetic, and mechanical. Each type works best in certain places and for specific tasks.

- Picking the right encoder depends on what you need. Think about accuracy, strength, and the environment it will be used in.

What is an Incremental Rotary Encoder?

Definition and purpose.

An incremental rotary encoder converts mechanical rotation into electrical signals. It helps you measure position, speed, and direction with precision. This device is essential in systems where accurate motion control is required. For example, it plays a key role in industrial automation, robotics, and motor control systems. By generating pulse signals, it provides feedback that ensures smooth and efficient operation. The encoder’s resolution, determined by the number of pulses per rotation, directly impacts its measurement accuracy. You can rely on this tool for cost-effective and reliable performance in various applications.

Key components and their roles.

An incremental rotary encoder consists of several critical components, each serving a specific function. Here’s a breakdown of these components:

| Component | Function |

|---|---|

| Rotary Disc | Contains alternating opaque and transparent sections to modulate light. |

| LED | Emits light that passes through the rotary disc. |

| Photo Detector | Captures light and converts it into electrical signals. |

| A and B Channels | Provide phase-shifted pulse outputs for direction detection. |

| Z Channel | Offers a single pulse per revolution for position verification. |

These components work together to generate signals that represent the movement of the encoder’s shaft. The A and B channels, with their 90-degree phase difference, allow you to determine the direction of rotation. The Z channel provides a reference pulse, ensuring accurate position tracking.

Incremental vs. absolute encoders.

When comparing incremental rotary encoders to absolute encoders, you’ll notice key differences in functionality and application. Incremental encoders generate pulse signals that require a reference point to determine position after power loss. In contrast, absolute encoders provide unique position values immediately upon power-up. This makes absolute encoders ideal for high-precision or safety-critical applications. However, incremental encoders are more cost-effective and versatile, making them suitable for tasks like speed measurement and general motion control. While absolute encoders retain position data during power outages, incremental encoders need to re-establish their starting point.

Both types of encoders have their strengths. Absolute encoders excel in applications requiring immediate position feedback, while incremental encoders offer simplicity and adaptability for a wide range of uses.

How Does an Incremental Rotary Encoder Work?

Signal generation and A/B channels.

An incremental rotary encoder generates signals through its A and B channels, which are quadrature signals. These channels produce square wave pulses with a 90-degree phase difference. This phase difference allows you to determine the direction of rotation. For instance, when channel A leads channel B, the encoder rotates in one direction. If channel B leads channel A, the rotation occurs in the opposite direction.

The A and B channels also enhance resolution by enabling four counts per electrical cycle. This is achieved by counting transitions in both channels, such as rising and falling edges. This method ensures precise position tracking, even in high-speed applications. The Z channel, often called the index channel, provides a single pulse per revolution. This pulse acts as a reference point, helping you verify the encoder’s position.

Key performance metrics for signal generation include the following:

| Metric | Description |

|---|---|

| Accuracy | Ensures precise position measurements for control applications. |

| Repeatability | Delivers consistent results across multiple measurements. |

| Signal Stability | Transmits accurate data without signal fluctuations. |

| Response Time | Reacts quickly to changes in displacement for real-time control. |

Measuring position, speed, and direction.

An incremental rotary encoder measures position, speed, and direction by converting mechanical rotation into electrical signals. The rotary disc, with alternating transparent and opaque sections, plays a crucial role. A light source projects light through the disc, and a photo detector captures the light passing through the transparent sections. This process generates pulse signals that represent movement.

Channels A and B produce square wave pulses, which help you determine the direction of rotation. By counting the number of pulses, you can calculate the position of the encoder. The speed is determined by measuring the frequency of the pulses. A higher frequency indicates faster rotation, while a lower frequency suggests slower movement.

| Component | Function |

|---|---|

| Rotary Disc | Converts mechanical rotation into electrical signals. |

| Light Source | Projects light through the disc’s transparent sections. |

| Pulse Signals | Represent movement through light passing transparent sections. |

| Channels A & B | Produce square wave pulses to determine direction. |

| Channel Z | Provides a single pulse per revolution for position verification. |

Role of pulses and resolution.

The resolution of an incremental rotary encoder depends on the number of pulses generated per revolution. A higher number of pulses results in greater resolution, allowing you to measure smaller increments of movement. For example, an encoder with 1,000 pulses per revolution can detect 0.36 degrees of rotation per pulse.

Pulses also play a vital role in determining speed and direction. By analyzing the frequency of the pulses, you can calculate the speed of rotation. The phase relationship between the A and B channels helps you identify the direction. This combination of high resolution and directional feedback makes incremental rotary encoders ideal for applications requiring precise motion control.

Types of Incremental Rotary Encoders

Incremental rotary encoders come in three main types: optical, magnetic, and mechanical. Each type has unique features that make it suitable for specific applications.

Optical encoders

Optical encoders use light to detect rotational movement. A light source shines through a rotary disc with alternating transparent and opaque sections. A photo detector captures the light, generating electrical signals that represent motion. These encoders are known for their high resolution and precision, making them ideal for applications requiring fine control, such as robotics and CNC machines.

Key features of optical encoders include:

- High precision: They often exceed 18-bit resolution, enabling ultra-precise tracking.

- Non-contact operation: This reduces wear and maintenance needs.

- Adaptability: They work well in both rotary and linear applications.

However, optical encoders are sensitive to dust and moisture, which can affect their performance. They are best suited for controlled environments where cleanliness is maintained.

Magnetic encoders

Magnetic encoders rely on magnetic fields to measure rotation. They use a magneto-resistive sensor to detect changes in the magnetic field as the encoder shaft rotates. These encoders are robust and can withstand harsh conditions, such as high humidity, dust, and vibrations.

Advantages of magnetic encoders include:

- Durability: They are designed to endure shocks and vibrations, making them reliable in industrial settings.

- Environmental resilience: They perform well in challenging environments, such as those with high dust or moisture levels.

- Versatility: They support various interfaces like PROFINET and EtherCAT, enhancing their compatibility with modern systems.

Magnetic encoders are commonly used in medical devices and industrial automation, where precision and robustness are critical.

Mechanical encoders

Mechanical encoders use physical contact to generate signals. A set of brushes or contacts interacts with a conductive pattern on the rotary disc, producing electrical pulses. These encoders are simple and cost-effective but less durable than optical or magnetic types.

Challenges faced by mechanical encoders include:

- Wear and tear: Physical contact leads to faster degradation, especially in dusty or humid environments.

- Environmental sensitivity: High humidity and dust can corrode components and reduce lifespan.

Despite these limitations, mechanical encoders are suitable for low-cost applications where high precision is not required.

| Metric | Optical Encoders | Magnetic Encoders | Mechanical Encoders |

|---|---|---|---|

| Environmental Resilience | Sensitive to dust and moisture | Robust in harsh conditions | Affected by dust and humidity |

| Resolution and Precision | High resolution for fine control | Sufficient for less precision-critical apps | Lower precision |

| Cost Considerations | Generally more expensive | Cost-effective alternatives | Most affordable |

| Durability and Reliability | Fragile, suited for clean environments | Highly durable and resilient | Prone to wear and tear |

| Maintenance Requirements | Requires frequent maintenance | Maintenance-friendly | High maintenance needs |

Each type of incremental rotary encoder offers unique benefits. Choosing the right one depends on your application’s precision, durability, and environmental requirements.

Advantages of Incremental Rotary Encoders

Cost-effectiveness and simplicity.

Incremental rotary encoders offer a budget-friendly solution for motion control applications. Their simple design makes them easier to implement compared to other sensor technologies. For example, they require fewer components and less complex circuitry, which reduces upfront costs. This simplicity also translates to quicker installation and lower maintenance requirements, saving you time and money in the long run.

| Aspect | Description |

|---|---|

| Affordability | Incremental rotary encoders provide a budget-friendly solution for motion control applications. |

| Durability | Built to last, reducing the frequency of replacements and repairs, thus lowering operational costs. |

| Ease of Integration | Simple design allows for easy setup and maintenance, making them ideal for basic applications. |

In comparison to other sensor technologies, incremental encoders stand out for their versatility. They perform well in a variety of applications, from conveyor systems to CNC machines, without the need for expensive upgrades or specialized components.

Key differences from absolute encoders.

The main difference between incremental and absolute encoders lies in how they track position. Incremental encoders measure relative changes in position by generating pulses, while absolute encoders provide the exact position of the shaft at any given time. This distinction makes incremental encoders more cost-effective but less suitable for applications requiring immediate position feedback after power loss.

- Absolute encoders retain position data during power outages, while incremental encoders need to re-establish a reference point.

- Incremental encoders emit pulses that must be counted to determine position, whereas absolute encoders deliver a specific angle of the shaft directly.

- The simpler design of incremental encoders results in lower costs, making them ideal for general motion control tasks.

Although absolute encoders excel in high-precision applications, incremental encoders remain a practical choice for most industrial and commercial uses.

Ideal use cases for incremental encoders.

Incremental rotary encoders are widely used in industries where cost-efficiency and reliability are priorities. For instance, they are perfect for conveyor systems, where basic speed and position feedback are sufficient. In CNC machines, they ensure reliable motion control without the need for expensive absolute encoders. Their robust design also makes them suitable for harsh environments, such as mining or heavy machinery operations.

| Case Study Title | Industry/Application | Key Features |

|---|---|---|

| SCARA Robot Uses Thru-Bore Encoder to Sort Recyclables | Robotics, Recycling | AI-driven sorting of materials using encoders |

| Tru-Trac Keeps Cut Lengths Accurate, Every Time | Custom Machinery | Encoder replacement to eliminate out-of-spec products |

| A Heavy Duty Accu-Coder® for a Demanding Application | Timber Harvesting | High durability and specific resolution for equipment |

These examples highlight the adaptability of incremental encoders. Whether you need precise motion feedback or a cost-effective solution for basic tasks, these encoders deliver reliable performance across a range of applications.

Applications of Incremental Rotary Encoders

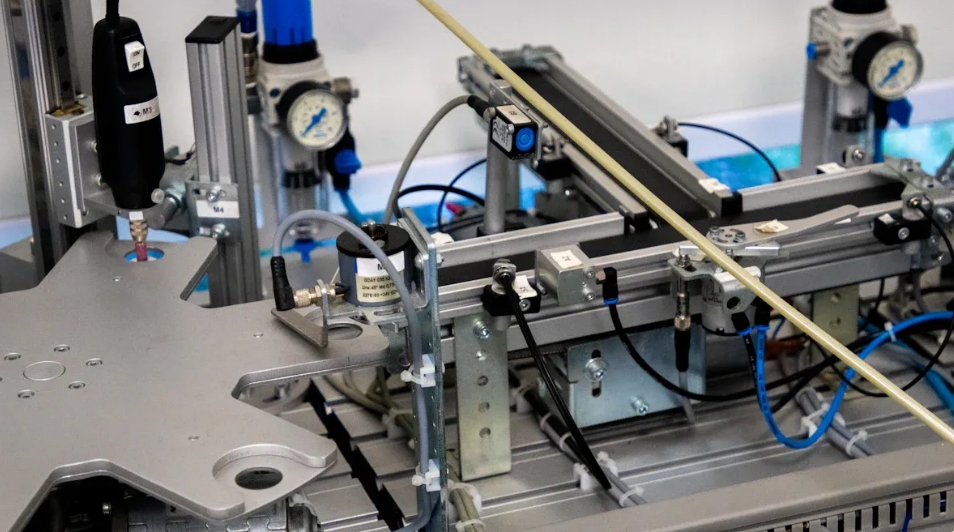

Industrial automation and robotics.

You’ll find incremental rotary encoders at the heart of industrial automation and robotics. These devices provide precise position and speed feedback, which is essential for controlling automated machinery. For example, in conveyor systems, they track item movement to ensure accurate sorting and placement. In robotics, they enable precise motion control, allowing robots to perform tasks like assembly and welding with high accuracy.

The growing demand for advanced automation technologies has significantly boosted the use of these encoders. Industries such as automotive, aerospace, and manufacturing rely on them to achieve precision and efficiency. Their cost-effectiveness and adaptability make them a preferred choice for many automation applications.

📊 Market Insight: The incremental encoders segment is expected to maintain a significant market share due to its wide applications and cost advantages.

| Case Study | Description |

|---|---|

| TONiC™ incremental encoders for Astrosysteme Austria | Enhanced performance and precision in robotics systems. |

| RESOLUTE™ encoders for IRELEC Alcen | Advanced synchrotron science through robotics systems. |

Motor control systems.

Incremental rotary encoders play a critical role in motor control systems. They provide real-time feedback on motor position, speed, and direction, ensuring smooth operation. This feedback allows you to make precise adjustments, enhancing energy efficiency and performance. For instance, in electric vehicles, these encoders optimize motor functionality, contributing to better energy management.

Their ability to deliver accurate data in dynamic systems makes them ideal for both small and large motors. Whether you’re working with industrial machinery or consumer-grade devices, these encoders ensure reliable and efficient motor control.

- Key Benefits:

- Precise feedback for position and speed.

- Improved energy efficiency in motor-driven applications.

- Real-time data delivery for dynamic adjustments.

Consumer electronics and other fields.

In consumer electronics, incremental rotary encoders are integral to innovations. They enhance productivity and minimize errors in automated workflows. For example, they provide critical feedback in motor control applications, allowing for precise adjustments. You’ll also see them in robotics, where they enable robots to perform complex tasks with high precision.

The rise of automation and Industry 4.0 has further increased the reliance on these encoders. Their ability to optimize processes through accurate position sensing makes them indispensable in modern technology. From home appliances to advanced medical devices, these encoders continue to drive innovation across various fields.

- Applications in Consumer Electronics:

- Position sensing in smart devices.

- Precision control in gaming peripherals.

- Enhanced functionality in automated home systems.

An incremental rotary encoder is a vital tool for measuring rotational movement and providing feedback. It converts mechanical motion into electrical signals, enabling precise control in various systems. You benefit from its cost-effectiveness, simplicity, and adaptability, making it a reliable choice for industrial automation, robotics, and motor control. Its ability to enhance accuracy and efficiency has made it indispensable in modern technology. By integrating these encoders, you contribute to advancing automation and achieving higher productivity in diverse applications.

FAQ

What is the difference between an incremental and an absolute rotary encoder?

An incremental encoder measures relative movement by generating pulses, while an absolute encoder provides the exact position of the shaft at any time. Incremental encoders are cost-effective and ideal for general motion control. Absolute encoders are better for applications requiring precise position data after power loss.

How do you calculate the resolution of an incremental rotary encoder?

You calculate resolution by dividing 360 degrees by the number of pulses per revolution. For example, an encoder with 1,000 pulses per revolution has a resolution of 0.36 degrees per pulse. Higher resolution means more precise measurements.

Can incremental rotary encoders work in harsh environments?

Yes, magnetic incremental encoders are designed for harsh conditions. They resist dust, moisture, and vibrations, making them suitable for industrial settings. Optical encoders, however, perform best in clean environments due to their sensitivity to contaminants.

What are the main applications of incremental rotary encoders?

You’ll find these encoders in industrial automation, robotics, and motor control systems. They also appear in consumer electronics, such as gaming devices and smart appliances. Their versatility makes them essential for precise motion control across various industries.

How do A and B channels help determine direction?

The A and B channels produce square wave signals with a 90-degree phase difference. By analyzing which channel leads, you can determine the direction of rotation. For example, if A leads B, the encoder rotates clockwise. If B leads A, it rotates counterclockwise.